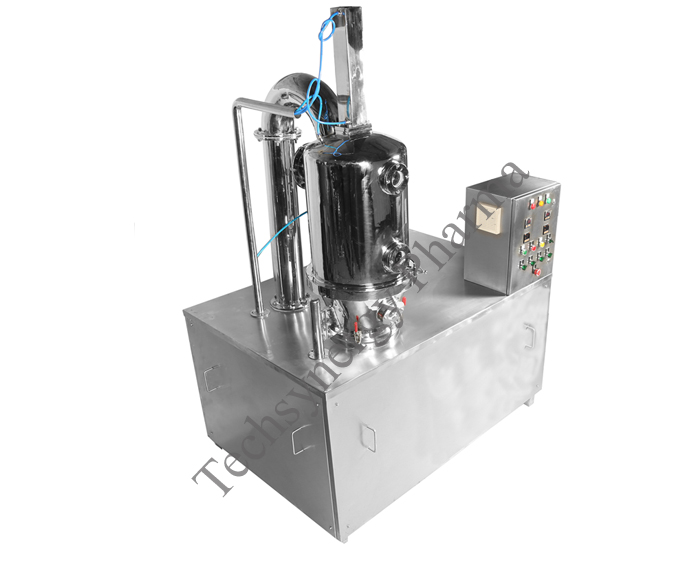

Granulation Machine -> Fluid Bed Dryer (FBD) Machine

"Fluid Bed Dryer" offers a comprehensible solution to the drying of wet granules or powder.

It utilizes the principle of passing the hot air at a high velocity through the bed of the material to be dried whilst making it fluidized. The blower situated on the exhaust side of the dryer creates the negative pressure which creates the induced draught and sucks in the fresh air which is filtered through 5/20 micron filter bag into the FBD. The stream of hot filtered air is introduced from the bottom of the product container holding the wet material. The powder container is provided with the Dutch sieve which retains the powder. As soon as the hot air passes through the container, it creates the fluidization and turbulence in the product container. Because of the fluidization, each particle is surrounded by the hot air, which leads to uniform heating and drying there by. Filter bags provided in the chamber prevent escaping of the particles from the Chamber.

The different options for heating can be offered such as electrical/steam etc. The drying time varies depending on the initial moisture content, drying temperature and ambient conditions and characteristics of the powder.

FBD is efficient in terms of saving energy and time. Our PLC can store the validated recipe which is available at any point of time and hence repeatability of the process can be ensured.

/ Features :- Uniform Drying with less Drying time

- Efficient in terms of saving energy & time

- Easy Dismantling of Dutch Sieve & Perforated Sheet at the Product container

- Provision of Online Sampling Device

- Fully Automatic Operation through PLC (Optional)

- Product Container with Stirrer (Optional)

- Flameproof Design (Optional)

- Minimum handling and more hygienic

- Top Mounted telescopic cylinder for auto bag shaking

- Clamp type bottom mesh for container

- cGMP with documentation

Capacity |

Automatic Grade |

Applications |

Pressure |

5 kg to 500 kg |

Automatic |

Pharmaceutical |

2 Bar |