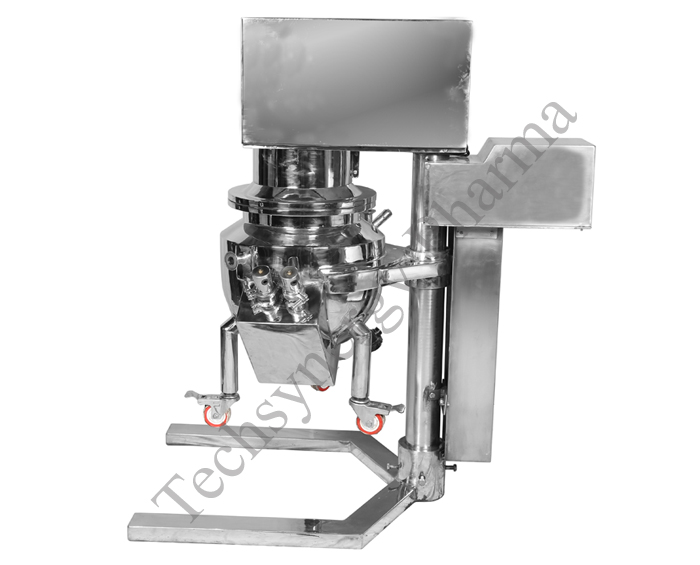

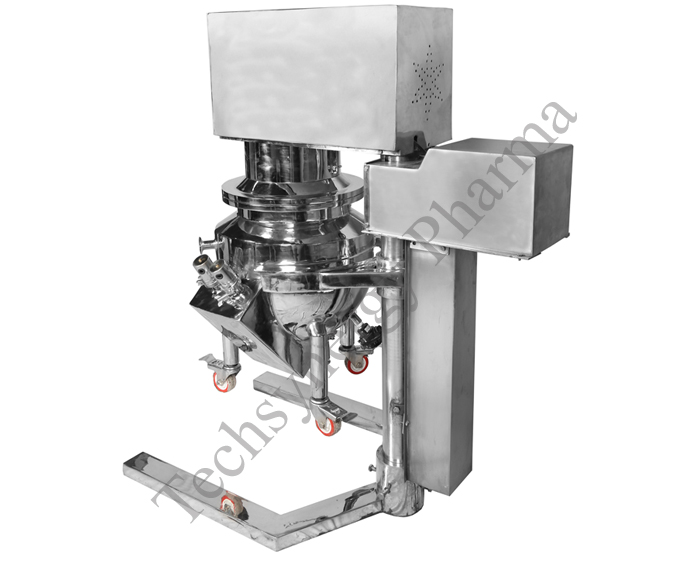

Granulation Machine -> Planetary Mixer Machine

Planetary mixer has great function of blending, shearing and dispersing, which suits well in dispersing and blending of materials in solid to solid, solid to liquid, liquid to liquid. Planetary mixer is widely used in chemical, food processing, drug producing, construction materials and light industries. Meanwhile, it also fits for cosmetic, ink, chocolate, sealing adhesive, ointment, paste materials etc.

Planetary Agitator MixerMixing elements rotate on a central axis in a vessel with each elements (Anchor agitator) simultaneously rotating on its own axis. There is option for agitator like: Single, Double & Triple blade. Planetary motion, generating a disturbance in the normally circular flow pattern in on axis thus to make the consummate materials' shearing, dispersing and blending. The blades of paddles are pitched to promote top to bottom flow. In addition, self adjustable scrapers are utilized to prevent the build-up of a stagnant film between the agitator and the vessel, and assure efficient heat transfer to product during heating and cooling steps.

Design Features :- Design compliance with cGMP

- Integrated Cleaning in Place-CIP. [Optional]

- Sterilizing In Place-SIP as an Option.

- Batch Size

- Available model 12 Liter to 600 Liter working Capacity.

- Materials

- Product Contact AISI 316L.

- Food Grade silicon rubber for seal.

- Agitator mixer & scrapper

- Mixing flow top to bottom in vertical axis.

- Anchor agitator with paddle with 45°C.

- Planetary rotating elements.

- Scrapper cleanly working.

- Optimize heat transfer.

- RPM sleeplessly with variable speed drive.

- Controls & Visualization

- Electric Controls with digital display.

- RPM and Process time entries.

- Temperature controls- Heat/cool.

- Vacuum start- Stop.

- Integrated Data Recording for batch.